#Rotary Encoders Industry

Explore tagged Tumblr posts

Text

How Can You Benefit from Using a Hollow Shaft Rotary Encoder in Automation

Discover how hollow shaft rotary encoders simplify installation, save space, and boost automation efficiency across industries like textile, packaging, and hoisting.

0 notes

Text

Shafted Hall Effect Sensors Market: Technological Advancements Reshaping Illumination Control

MARKET INSIGHTS

The global Shafted Hall Effect Sensors Market size was valued at US$ 567.8 million in 2024 and is projected to reach US$ 945.2 million by 2032, at a CAGR of 7.60% during the forecast period 2025-2032.

Shafted Hall effect sensors are compact magnetic field sensing devices with injection-molded housings designed for precision measurement in rotary and linear motion applications. These sensors operate on the Hall effect principle, where they detect changes in magnetic fields to measure position, speed, or directional movement. Their rugged construction allows operation across wide temperature ranges (-40°C to 150°C) while maintaining resistance to moisture and environmental contaminants.

The market growth is driven by increasing automation in industrial sectors and rising demand for contactless sensing solutions in automotive applications. While the industrial equipment segment currently dominates with over 45% market share, the automotive sector is witnessing accelerated adoption due to electrification trends. Recent advancements include miniaturized form factors with improved signal-to-noise ratios, enabling higher precision in tight spaces. Key players like Sensata Technologies and TE Connectivity are expanding their portfolios with IoT-enabled sensors featuring integrated diagnostics.

MARKET DYNAMICS

MARKET DRIVERS

Growing Industrial Automation to Fuel Demand for Shafted Hall Effect Sensors

The rapid expansion of industrial automation across manufacturing sectors is driving significant demand for shafted Hall effect sensors. These sensors play a critical role in position sensing, speed detection, and angular measurement in automated systems. The global industrial automation market is projected to maintain a robust growth rate, creating parallel opportunities for shafted Hall effect sensor manufacturers. Their durability, precision, and ability to operate in harsh environments make them indispensable components in modern automated production lines. Recent advancements in Industry 4.0 technologies have further intensified this demand, particularly for sensors that can deliver accurate real-time data for process optimization.

Electric Vehicle Revolution to Accelerate Market Expansion

The automotive industry’s accelerated shift toward electric vehicles presents a substantial growth opportunity for shafted Hall effect sensors. These sensors are essential components in EV powertrains, battery management systems, and motor control units. With global EV sales surpassing 10 million units annually and projected to grow exponentially, the demand for reliable position sensing solutions is reaching unprecedented levels. Major automotive manufacturers are increasingly specifying shafted Hall effect sensors for their compact size, resistance to vibration, and ability to operate in electromagnetic interference-rich environments characteristic of electric vehicles.

Furthermore, government initiatives supporting EV adoption across major economies are creating favorable conditions for sensor manufacturers:

➤ Several national policies now include stringent requirements for position sensing accuracy in EV components, directly benefiting high-performance Hall effect sensor suppliers.

MARKET RESTRAINTS

Intense Price Competition from Alternative Technologies to Limit Growth

While shafted Hall effect sensors offer numerous advantages, the market faces considerable pressure from competing technologies such as optical encoders and inductive sensors. These alternatives have seen significant price reductions in recent years, making them attractive options for cost-sensitive applications. The average selling price for standard shafted Hall effect sensors has declined steadily, squeezing profit margins for manufacturers. This pricing pressure is particularly acute in high-volume consumer applications where even marginal cost differences significantly influence purchasing decisions.

Additionally, the growing adoption of integrated sensor solutions that combine multiple sensing modalities presents a competitive challenge for standalone Hall effect sensor providers.

MARKET CHALLENGES

Complex Supply Chain Disruptions to Impact Production Capacities

The shafted Hall effect sensor market continues to grapple with multifaceted supply chain challenges that emerged following recent global disruptions. Semiconductor material shortages have particularly affected sensor production, given their reliance on specialized magnetic materials and integrated circuits. Lead times for certain critical components have extended dramatically, forcing manufacturers to either maintain larger inventories or risk production delays. These challenges are compounded by rising transportation costs and geopolitical factors affecting rare earth material supplies essential for sensor manufacturing.

Other Significant Challenges Include:

Technical Limitations in Extreme Environments While shafted Hall effect sensors perform well in most industrial conditions, their reliability can be compromised in extremely high-temperature or highly corrosive environments. This limitation restricts their applicability in certain heavy industrial and aerospace applications where alternative technologies may be preferred.

Miniaturization Demands The persistent industry trend toward smaller form factors presents engineering challenges for maintaining sensor accuracy and durability in ever-shrinking packages, requiring continuous R&D investments.

MARKET OPPORTUNITIES

Emerging IoT Applications to Create New Growth Verticals

The rapid proliferation of Industrial Internet of Things (IIoT) deployments is opening substantial new opportunities for shafted Hall effect sensor manufacturers. These sensors are increasingly being integrated into predictive maintenance systems and smart equipment monitoring solutions. The ability of Hall effect sensors to provide reliable, contactless position data makes them ideal for IIoT applications where continuous monitoring is essential. Market analysts project strong growth in this segment as industries increasingly adopt condition-based maintenance strategies that rely on real-time sensor data.

Medical Device Innovations to Drive Premium Sensor Demand

The medical equipment sector is emerging as a high-growth market for precision shafted Hall effect sensors. These components are finding increasing use in advanced imaging systems, robotic surgical equipment, and portable medical devices. The medical sensor market commands premium pricing due to stringent reliability requirements and regulatory certifications. Several leading sensor manufacturers have recently introduced medical-grade shafted Hall effect sensors with enhanced EMI resistance and sterilization capability, specifically targeting this lucrative segment.

SHAFTED HALL EFFECT SENSORS MARKET TRENDS

Automotive Electrification Drives Demand for Hall Effect Sensors

The global shafted Hall Effect sensors market is witnessing significant growth, driven primarily by the increasing electrification of automotive systems. These compact, durable sensors play a critical role in modern vehicle systems, enabling precise angular position sensing in throttle valves, pedal positions, and transmission systems. With electric vehicle production expected to grow at a CAGR of over 26% through 2030, OEMs are incorporating more Hall Effect sensors to monitor motor position and speed in electrified powertrains. The automotive sector now accounts for nearly 42% of all shafted Hall Effect sensor applications globally.

Other Key Trends

Miniaturization and IoT Integration

The demand for compact, rugged position sensors has increased across industrial automation and consumer electronics sectors. Shafted Hall Effect sensors – combining high accuracy with small form factors – are increasingly being integrated into IoT-enabled devices. Their ability to operate in harsh environments without physical contact makes them ideal for smart factory equipment, where they monitor parameters like fluid levels, valve positions, and actuator movements. The industrial segment is projected to account for over 28% of market revenue by 2030 as Industry 4.0 adoption accelerates.

Technological Advancements in Sensing Capabilities

Recent innovations are expanding the capabilities of shafted Hall Effect sensors to meet evolving industry needs. Rotary Hall Effect sensors now achieve angular resolutions below 0.1°, while linear variants offer sub-millimeter precision. Manufacturers are also developing multi-axial sensing solutions that combine position and speed measurement in single packages, reducing system complexity. These advancements are particularly valuable in medical devices and robotics, where precision motion control is critical. The integration of self-diagnostics and digital interfaces (like I²C and SPI) is further enhancing their utility in connected industrial systems.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Global Expansion Drive Market Competition

The global Shafted Hall Effect Sensors market is moderately fragmented, with established multinational corporations competing alongside specialized regional players. Sensata Technologies leads the market with its comprehensive portfolio of rugged, high-performance sensors designed for automotive and industrial applications. The company’s strong engineering capabilities and vertically integrated manufacturing give it a competitive edge in pricing and quality control.

TE Connectivity and Amphenol Corporation maintain significant market positions due to their extensive distribution networks and ability to provide customized sensor solutions. These companies have strategically expanded their production facilities in Asia to capitalize on growing demand from China’s automotive sector.

Several European manufacturers like Gefran and Elen srl have carved out strong niches in precision industrial applications. Their expertise in developing sensors that operate reliably in harsh environments has made them preferred suppliers for heavy machinery and automation systems.

Meanwhile, DiscoverIE Plc and Novotechnik are investing heavily in next-generation Hall Effect technologies that integrate digital interfaces and IoT capabilities. These enhancements allow for predictive maintenance features – a key value proposition for industrial customers looking to minimize downtime.

List of Key Shafted Hall Effect Sensor Manufacturers

Sensata Technologies (U.S.)

TE Connectivity (Switzerland)

Amphenol Corporation (U.S.)

Gefran (Italy)

Elen srl (Italy)

Servotech Instrumentation (India)

P3 America (U.S.)

Novotechnik (Germany)

Vishay (U.S.)

DiscoverIE Plc (U.K.)

Segment Analysis:

By Type

Rotary Hall Effect Sensor Segment Leads Due to Wide Industrial and Automotive Applications

The market is segmented based on type into:

Rotary Hall Effect Sensor

Linear Hall Effect Sensor

By Application

Industrial Equipment Segment Dominates Market Owing to Automation and Process Control Requirements

The market is segmented based on application into:

Industrial Equipment

Automotive

Telecommunications Equipment

Others

By End-User

Manufacturing Sector Holds Major Share Due to Precision Measurement Needs

The market is segmented based on end-user into:

Manufacturing Industries

Automotive OEMs

Telecom Providers

Consumer Electronics

Others

Regional Analysis: Shafted Hall Effect Sensors Market

North America The North American market for shafted Hall effect sensors is driven by strong demand from the industrial automation and automotive sectors, particularly in the U.S. and Canada. The U.S. accounts for the majority of the regional market due to heavy investments in Industry 4.0 adoption, with leading manufacturers such as Sensata Technologies and TE Connectivity headquartered here. Stringent safety regulations in automotive applications, particularly in electric vehicles (EVs), further boost demand. However, the market faces challenges from increasing competition from alternative sensing technologies and supply chain disruptions.

Europe Europe remains a key market for shafted Hall effect sensors, driven by advancements in industrial automation and strong automotive manufacturing activities in Germany, France, and Italy. The EU’s focus on precision engineering and energy-efficient solutions supports sensor adoption in high-performance applications. Market leaders like Gefran and Novotechnik have capitalized on the region’s emphasis on quality-controlled manufacturing. However, strict regulatory compliance and elevated production costs compared to Asian manufacturers present constraints for market expansion.

Asia-Pacific The Asia-Pacific region dominates global consumption of shafted Hall effect sensors, primarily due to rapid industrialization in China, Japan, and India. China, being a manufacturing powerhouse, leads in both production and utilization of these sensors across automotive and telecommunications sectors. Cost-effectiveness and scalability of local suppliers such as Vishay and Servotech Instrumentation fuel market growth. Meanwhile, Japan’s precision manufacturing industry and India’s expanding automation sector contribute significantly. Though price sensitivity remains a challenge, increasing investments in smart manufacturing are expected to sustain demand.

South America Market growth in South America is gradual, influenced by Brazil’s and Argentina’s emerging industrial sectors. While adoption of shafted Hall effect sensors is primarily seen in automotive manufacturing, economic instability limits widespread industrial automation. Local players face competition from imported products, yet the growing focus on upgrading manufacturing facilities hints at untapped potential. Regulatory gaps and limited R&D investments hinder faster technological adoption despite the expanding market.

Middle East & Africa This region shows moderate demand, primarily driven by industrial and automotive applications in GCC countries such as Saudi Arabia and the UAE. Investments in smart infrastructure and gradual industrial diversification are creating opportunities for sensor integration. However, the market’s growth remains constrained by reliance on imports and limited local manufacturing capabilities. Though still nascent, strategic collaborations with international players like Amphenol Corporation could enhance market penetration in the long term.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Shafted Hall Effect Sensors markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global Shafted Hall Effect Sensors market was valued at USD 260 million in 2024 and is projected to reach USD 380 million by 2032, growing at a CAGR of 4.8%.

Segmentation Analysis: Detailed breakdown by product type (Rotary Hall Effect Sensor, Linear Hall Effect Sensor), application (Industrial Equipment, Automotive, Telecommunications Equipment), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America (USD 85 million in 2024), Europe, Asia-Pacific (fastest growing at 6.2% CAGR), Latin America, and Middle East & Africa, including country-level analysis.

Competitive Landscape: Profiles of leading market participants including Sensata Technologies (12% market share), TE Connectivity, Amphenol Corporation, and Vishay, covering product portfolios, R&D investments, and strategic developments.

Technology Trends & Innovation: Assessment of miniaturization trends, integration with IoT systems, and advancements in magnetic sensing technologies.

Market Drivers & Restraints: Evaluation of factors including industrial automation growth, automotive electrification trends, and challenges related to raw material pricing volatility.

Stakeholder Analysis: Strategic insights for sensor manufacturers, OEMs, system integrators, and investors regarding market opportunities and competitive positioning.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/laser-diode-cover-glass-market-valued.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/q-switches-for-industrial-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ntc-smd-thermistor-market-emerging_19.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lightning-rod-for-building-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cpe-chip-market-analysis-cagr-of-121.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/line-array-detector-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/tape-heaters-market-industry-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wavelength-division-multiplexing-module.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/electronic-spacer-market-report.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/5g-iot-chip-market-technology-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/polarization-beam-combiner-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/amorphous-selenium-detector-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/output-mode-cleaners-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digitally-controlled-attenuators-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/thin-double-sided-fpc-market-key.html

0 notes

Text

Understanding the Role of Hollow Shaft Rotary Encoders in Modern Robotics

Introduction to Rotary Encoders in Robotics

Rotary encoders are fundamental components in robotic systems, serving as critical feedback devices that measure the rotation, position, and direction of motor shafts. These sensors translate mechanical motion into electrical signals, which control systems then interpret to ensure precise movement. Among the various types of rotary encoders, hollow shaft rotary encoders have emerged as a key player due to their compact design, ease of integration, and high reliability. As robotics continues to permeate sectors like manufacturing, healthcare, logistics, and consumer electronics, understanding the specific contributions of hollow shaft rotary encoders becomes vital. Their importance lies not only in their functional capabilities but also in how they influence design flexibility and performance optimization in robotic applications. By integrating seamlessly into existing architectures, these encoders reduce mechanical complexity while improving feedback accuracy. This comprehensive examination will explore how these components are revolutionizing modern robotics, from their design advantages to their roles in various robotic subsystems.

Evolution of Rotary Encoders and Robotic Needs

The development of rotary encoders parallels the evolution of robotics itself. Early robotic systems relied on open-loop controls, often leading to inaccuracies and inefficiencies. As the demand for precision and repeatability grew, rotary encoders became indispensable. Initially, these sensors were bulky and susceptible to environmental interference. Over time, however, innovations in materials, signal processing, and miniaturization led to more robust and compact designs. Hollow shaft rotary encoders, in particular, emerged as a response to the need for space-saving yet highly accurate feedback devices. Robotics has evolved from simple pick-and-place machines to complex, autonomous entities requiring precise coordination across multiple axes. This shift necessitated encoders capable of delivering consistent, high-resolution feedback without contributing to design bulk. In mobile robots, surgical devices, and industrial arms, space is a premium commodity. Hollow shaft encoders allow engineers to route cables or mechanical shafts through the encoder's center, optimizing spatial configuration and reducing wear on moving parts. This evolution marks a significant turning point in the interplay between sensor technology and robotic capability.

Anatomy of a Hollow Shaft Rotary Encoder

At its core, a hollow shaft rotary encoder consists of a rotor, stator, and signal processing circuitry housed in a compact unit. What distinguishes it from other encoder types is the central hollow section through which a shaft or cabling can pass. This seemingly simple design offers substantial advantages. The rotor attaches directly to the rotating shaft, while the stator remains fixed to the structure. As the shaft turns, the encoder senses the angular displacement and transmits corresponding electrical signals. These signals may be digital or analog, depending on the encoder type and application. Typically, hollow shaft encoders utilize optical, magnetic, or capacitive technologies to detect movement. Optical encoders, for instance, use a light source and a photo-detector array to interpret interruptions in a coded disc. This method provides high-resolution data, essential for robotic operations requiring micrometer-level precision. Additionally, many hollow shaft encoders incorporate features like integrated bearings, multi-turn tracking, and error correction protocols, ensuring they maintain accuracy even under high-speed or high-vibration conditions.

Integration in Robotic Joint Systems

One of the primary applications of hollow shaft rotary encoders in robotics is within joint systems. Whether in humanoid robots or articulated industrial arms, joint movement must be monitored and controlled with utmost precision. Hollow shaft encoders facilitate this by being mounted directly onto the joint actuators, enabling real-time position feedback. Their hollow design allows power and data cables to pass through the joint axis, reducing external cabling and potential points of failure. This configuration not only enhances the mechanical efficiency of the joint but also simplifies maintenance and design. In collaborative robots, or cobots, where safety and fluid motion are paramount, these encoders help ensure smooth articulation and responsive behavior. They support closed-loop control systems that adjust motor output dynamically based on encoder feedback. This loop is crucial for tasks like pick-and-place operations, precision welding, or surgical manipulations, where even millimeter-level deviations can compromise functionality or safety. By offering a balance of compactness, accuracy, and reliability, hollow shaft rotary encoders are central to robotic articulation systems.

Enhancing Mobility in Autonomous Robots

Autonomous mobile robots (AMRs) require robust sensory systems to navigate complex environments accurately. Hollow shaft rotary encoders play an essential role in this context by providing reliable feedback on wheel or track rotation. Unlike incremental encoders that only track changes in position, absolute feedback systems offer the advantage of positional memory. This becomes crucial in navigation, where knowing the robot's exact orientation at any given time determines path planning and obstacle avoidance efficacy. In differential drive systems, for instance, encoders mounted on each wheel shaft measure relative speeds and directions, allowing for accurate steering and speed control. The compact nature of hollow shaft encoders is especially beneficial in mobile platforms, where every millimeter of space impacts battery size, payload capacity, or sensor load. Their integration also enhances durability since fewer external mechanical parts mean less exposure to dust, moisture, or mechanical wear. This synergy of design efficiency and functional robustness makes hollow shaft encoders indispensable in robotic mobility subsystems.

Role in Precision Tasks and Fine Manipulation

Modern robotics increasingly involves tasks requiring fine motor control, such as electronic assembly, 3D printing, and medical interventions. In these scenarios, the encoder’s resolution and responsiveness directly impact task accuracy. Hollow shaft rotary encoders contribute significantly by enabling micro-adjustments based on real-time positional data. In robotic arms used for electronic manufacturing, for instance, components must be placed with sub-millimeter accuracy. The encoder's feedback ensures that the tool tip follows the programmed path without deviation. Similarly, in 3D printing, layer consistency and nozzle positioning depend heavily on precise rotary feedback. Medical robotics, particularly in minimally invasive surgery, represents another frontier where precision is non-negotiable. Here, hollow shaft encoders are used in tool actuation systems, allowing surgeons to perform complex procedures remotely with high confidence in the robot's positional accuracy. The encoders’ inherent design also aids in sterilization and integration within tight surgical tool assemblies. Thus, their role extends from mechanical feedback to enabling new capabilities in high-precision robotic tasks.

Environmental Robustness and Industrial Viability

Robotic systems often operate in harsh environments—factories, outdoor settings, or hazardous locations. Devices integrated into such systems must exhibit resilience to temperature fluctuations, vibrations, dust, and moisture. Hollow shaft rotary encoders are increasingly engineered with these challenges in mind. Manufacturers offer variants with IP-rated enclosures, corrosion-resistant materials, and sealed optical systems. This robustness allows them to function reliably in automotive assembly lines, mining robots, or agricultural drones. In temperature-controlled warehouse automation, for example, encoders must perform consistently despite frequent exposure to cold or variable humidity levels. The absence of exposed cables and the encoder’s enclosed design minimize contamination risks and mechanical wear. These features contribute to lower maintenance demands and longer operational lifespans, which are critical in high-throughput industrial settings. Moreover, their compatibility with various communication protocols—such as EtherCAT, CANopen, and SSI—ensures that they can be integrated into diverse control architectures without extensive modification. This adaptability further cements their place in modern industrial robotics.

Supporting Safety and Redundancy Mechanisms

Safety is a fundamental concern in robotics, particularly in collaborative or human-facing environments. Encoders play a vital role in ensuring operational safety by providing accurate position feedback for motion verification and error detection. Hollow shaft rotary encoders are especially suited for redundant systems, where multiple sensors verify each other's outputs. This redundancy ensures that if one sensor fails, the system can continue operating safely or shut down in a controlled manner. In safety-rated robotic arms, encoders are often employed in tandem with other sensors to monitor limits and ensure compliance with predefined safety envelopes. Their high resolution and low latency make them ideal for such critical feedback loops. Additionally, their compact form factor allows for integration into secondary safety circuits without adding bulk. The feedback from these encoders also enables soft-limit programming, which prevents actuators from moving beyond safe zones. In service robots or exoskeletons, where human safety is paramount, this encoder-driven feedback becomes essential for real-time decision-making and reactive control.

Future Outlook: Smart Integration and Predictive Maintenance

As robotics evolves towards greater autonomy and intelligence, the role of feedback devices like hollow shaft rotary encoders is also transforming. Modern encoders are increasingly being equipped with smart features such as self-diagnostics, condition monitoring, and real-time data streaming. These capabilities feed into predictive maintenance systems, helping operators detect wear or misalignment before it causes failure. For example, by monitoring signal consistency or rotational anomalies, the encoder can alert the system to potential mechanical issues. This proactive approach reduces downtime and extends the life of robotic assets. Furthermore, as artificial intelligence becomes integral to robotics, encoder data can be used to train machine learning models for movement optimization and adaptive control. Smart encoders also support advanced communication standards that facilitate seamless integration into IoT-enabled infrastructures. This trend indicates a shift from passive sensing to active data contribution, where encoders not only report motion but also enhance system intelligence. Such evolution positions hollow shaft rotary encoders as foundational components in next-generation robotic ecosystems.

Precision Engineering Meets Practical Application

The intersection of precision engineering and practical robotic application is where hollow shaft rotary encoders demonstrate their full potential. As manufacturing tolerances tighten and robotic roles diversify, the demand for encoders that can deliver high-resolution feedback in compact, rugged packages continues to grow. These devices are not only vital for motion tracking but also contribute to reducing system complexity, enhancing safety, and enabling adaptive control. Their utility spans industries and use-cases, from autonomous warehouse robots to robotic-assisted surgery. As designers push the boundaries of what robots can achieve, they increasingly turn to encoders that offer a balance of size, accuracy, and integration flexibility. Among these, the hollow shaft rotary encoder stands out for its ability to combine mechanical elegance with technical performance. Its role in facilitating the compact, precise, and reliable movement is central to the continued advancement of robotics.

Enhancing Control Through Advanced Feedback Systems

In many robotic systems, especially those with complex kinematics, advanced feedback is necessary to synchronize multiple actuators. Here, the absolute rotary encoder proves instrumental. By providing unique position values that do not require recalibration after power loss, these encoders enhance system reliability and responsiveness. This becomes particularly valuable in automated systems that must resume operation immediately after interruptions. Their use simplifies control algorithms and reduces computational overhead, which in turn allows for more fluid and responsive robotic behavior. From industrial automation lines to mobile robotic platforms, absolute encoders bring consistency and predictability, even under dynamic load changes or complex trajectories. When integrated with real-time control loops, they enable smoother transitions, better torque management, and reduced mechanical stress. These benefits contribute to more agile and longer-lasting robotic systems.

Meeting Modern Demands with Cutting-Edge Solutions

The robotic landscape is shifting rapidly, driven by needs for flexibility, scalability, and intelligence. In this context, the absolute position encoder emerges as a critical component, especially in scenarios where exact positioning is non-negotiable. Whether it’s aligning robotic cameras, controlling prosthetic limbs, or managing the angular position of robotic grippers, these encoders deliver the granularity required for high-precision tasks. They also facilitate seamless feedback for AI-driven decisions, particularly in adaptive robotics that interact with unpredictable environments. The encoder's ability to provide exact position data without drift ensures consistent performance across repetitive tasks. In emerging sectors like robotics-as-a-service or modular robotics, where plug-and-play compatibility is essential, these encoders ensure that new modules or replacements can integrate smoothly and function reliably. As expectations for precision, speed, and autonomy grow, so too does the importance of dependable, high-performance feedback systems like the absolute position encoder.

0 notes

Text

Smart Encoder Selection for Efficient Manufacturing

Choosing the right smart encoder is essential for efficient manufacturing. A smart encoder helps monitor motion, speed, and position with high accuracy, improving overall automation. It supports real-time feedback, ensuring smooth machine operation and reduced downtime. With various types like rotary and linear encoders, manufacturers can select the right one based on application needs. Smart encoders are durable, energy-efficient, and easy to integrate with control systems. They play a major role in increasing productivity and maintaining consistent product quality. For industries aiming to streamline processes, smart encoder selection is key to achieving better performance and reliability in manufacturing systems.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Encoder#manufacturing unit#sensor#plc#type of encoders

0 notes

Text

PCB Components: Active & Interactive – A Deep Dive Into Buttons, Switches, And LED Integration

Printed Circuit Boards (PCBS) are the foundation of modern electronic devices, and the components mounted on them determine the function, interactivity, and performance of the final product. Among these components, those that add user interaction and visual feedback are especially important. In this article, we explore key PCB components that are both active and interactive, including LED light components, PCB buttons, touch buttons, PCB switches, and circuit board switches.

The Role of Active and Interactive Components in PCBS

While resistors, capacitors, and microcontrollers form the brain and nervous system of a circuit, interactive components are the parts users directly engage with. These include input and output elements like switches, buttons, and LEDS that provide feedback or control functionality. Their design, placement, and integration into the PCB layout determine the user experience and overall product usability.

LED Light Components – Visual Feedback and Functionality

LED light components are perhaps the most widely used visual indicators in electronics. These can signal power status, indicate processing states, or serve as alerts. In modern consumer electronics, RGB LEDS are often integrated to offer multi-colour feedback in a single package. Their compact form makes them ideal for PCB integration. Designers typically use surface-mount or through-hole LEDS depending on the size constraints and the manufacturing process.

LEDs can also be interactive. For example, when integrated with a light sensor or a touch button, an LED can respond to environmental changes or user actions, enhancing the device's intuitive feel.

PCB Buttons – Tactile and Durable

A PCB button refers to a mechanical push-button mounted directly onto the circuit board. These are common in devices requiring tactile feedback, such as remote controls, handheld gadgets, and industrial interfaces. Typically made of conductive rubber or metal domes, PCB buttons close a circuit when pressed, sending a signal to the controller.

Their mechanical durability, ease of replacement, and firm tactile response make them ideal for products that demand consistent user interaction. Proper design and spacing are crucial to ensure longevity and reliability.

Touch Buttons – Sleek and Modern

Touch buttons are a modern alternative to mechanical buttons. They use capacitive or resistive sensing to detect a user’s finger. These buttons provide a seamless, flat surface and are often used in devices like microwaves, induction cookers, and smartphones. Because they have no moving parts, they tend to last longer and are more resistant to dust and moisture.

Touch buttons are typically implemented by adding a conductive pad on the PCB, connected to a capacitive sensing IC. With appropriate firmware, touch sensitivity can be fine-tuned for better performance across different environments.

PCB Switches – Controlling Power and Modes

PCB switches refer to various types of toggle, slide, or rocker switches mounted on a circuit board. They allow users to change operating modes, turn devices on or off, or control specific functions. These switches are ideal for applications where physical state changes are necessary and must be visually verified (e.g., ON/OFF positions).

From DIP switches used in older hardware settings to modern micro slide switches in wearable tech, the variety of PCB switches allows for wide application flexibility.

Circuit Board Switch – A Broad Term with Specific Use

The term circuit board switch is often used interchangeably with PCB switches, but it can also refer to any electrical switch mounted on a board. This includes everything from tactile buttons to rotary encoders. These switches play a crucial role in routing electrical signals and enabling user control.

Summing It Up

Understanding and integrating active and interactive PCB components like LED light components, PCB buttons, touch buttons, PCB switches, and circuit board switches is essential for creating intuitive and functional electronic devices. Designers must consider user experience, durability, and responsiveness when selecting these elements. As technology continues to advance, these interactive components will evolve to provide smarter, sleeker, and more seamless user interfaces.

0 notes

Text

Heidenhain Encoder Dealers, Distributors & Suppliers in India - Omkar Supranational

Explore Heidenhain rotary, angle, and linear encoders known for precision, accuracy, and repeatability. Omkarsupra is a trusted Heidenhain encoder distributor for automation, automotive, and energy industries. We provide fast encoder replacements and genuine accessories for all industrial applications.

0 notes

Text

Counting on Precision: Rotary Contactors in American Manufacturing

In factories across the USA, production lines often combine high-tech automation with tried-and-true mechanical devices. One unassuming component that engineers continue to count on for accuracy is the rotary contactor. It may not flash or beep, but this simple device plays a big role in keeping counts and measurements spot-on – from tallying product units to gauging lengths of material. Let’s explore how a rotary contactor enhances production precision and why it remains a staple in American manufacturing.

Old-School Gadget, Modern-Day Reliability

Rotary contactors have been around for decades, long before today’s digital sensors and IoT-enabled devices. Yet, many U.S. factories still rely on them because of one simple reason: they work, and they work practically anywhere. In an age where high-tech sensors can sometimes glitch due to electrical noise or require complex setup, a rotary contactor offers a refreshingly simple and foolproof solution. It doesn’t need a power supply to do its basic job of counting; a rotating shaft and a magnet or cam inside do all the work to close a switch at just the right moment. This means even if your production floor is dusty, hot, or subject to electrical interference, the contactor keeps on clicking away reliably. American manufacturers have learned that mixing a bit of old-school tech with modern automation can actually boost reliability – the rotary contactor is often that dependable backup that ensures the counts keep coming even when fancier systems hiccup.

Counting Rotations, Lengths, and More

When people hear “rotary contactor,” they often think of simply counting rotations – like how many times a machine arm goes around. And indeed, that’s a core use: for example, counting each revolution of a shaft to know how many cycles a machine has completed. But rotary contactors can do more than just count turns. Pair one with a measuring wheel, and suddenly you have a device that can measure length of material. This is a common trick in industries like textiles, paper, or metal fabrication in the USA: as a sheet or strip of material moves, the wheel turns and the contactor clicks off pulses corresponding to distance. It’s a straightforward way to track how many feet or meters of material have been fed or processed – essentially acting as a basic flat material measuring machine without needing elaborate electronics. Of course, for ultra-precise length measurements or higher resolution, many might opt for advanced encoders. But if one pulse per unit of length is enough, a rotary contactor with a wheel gets the job done with minimal fuss.

Real-World Examples Across the USA

In real-world operations, rotary contactors quietly contribute to accuracy in various ways. Imagine a paper mill in the USA Northeast: as giant rolls of paper are wound, a contactor counts each rotation of the spool. After a set number of turns (translating to a specific length of paper), it signals a cutter to slice the roll at just the right point. Or picture a Midwest packaging plant where a contactor tracks each cycle of a rotary indexing table, ensuring every station (filling, capping, labeling) has completed its task in sync – any missed beat and the contactor would alert operators. Even small workshops benefit: a custom machine builder in the USA might install a rotary contactor on a piece of legacy equipment to give it a simple counting capability without overhauling the entire system. These examples show how from coast to coast, this device adapts to needs both big and small, providing a layer of assurance that “yes, that rotation happened” or “that length of material passed by” when it’s supposed to.

Easy Integration with Modern Systems

Another reason rotary contactors remain relevant is how easily they integrate with modern counting and control systems. The output of a rotary contactor is just an electrical contact closure (basically like a momentary button press), which nearly any counter, PLC, or industrial controller can accept as an input. This means you can connect a rotary contactor to a digital counter display, a programmable logic controller, or even into a PC-based data acquisition system with minimal hassle. It acts as a simple sensor that provides a dependable “tick” each time an event occurs. Many facilities in the USA pair these contactors with electronic counters or PLC programs to trigger actions – for example, stopping a machine after a certain count, or displaying the throughput count on a screen for operators. In essence, the rotary contactor bridges the gap between the mechanical world and the digital world: you get the ruggedness of a mechanical device and the intelligence of modern electronics working together. It’s a relationship that keeps production data flowing smoothly.

Conclusion: In summary, the rotary contactor exemplifies how classic engineering can complement modern manufacturing. Its presence on factory floors across the United States is a testament to its reliability and utility. When precision counts (literally!), having a rotary contactor in the mix can make all the difference in keeping operations smooth and counts accurate. So whether you're troubleshooting an existing line or designing a new system, don't overlook this proven solution. To learn more about rotary contactors and explore a full range of industrial automation tools, you can visit our main website anytime. Sometimes, a little old-school ingenuity is just what your high-tech production line needs to stay on the cutting edge.

0 notes

Text

Automation Control Components in Singapore | Hikari Automation Systems Pte Ltd

Automation plays a crucial role in modern industries, enhancing efficiency, precision, and productivity. In Singapore, businesses across various sectors rely on high-quality automation control components to optimize operations. Hikari Automation Systems Pte Ltd is a leading provider of reliable automation solutions, offering a comprehensive range of automation control components to meet industrial needs.

What Are Automation Control Components?

Automation control components are essential elements that ensure smooth and precise machine operations in industrial settings. These components help monitor, regulate, and control automated systems, reducing human intervention while improving accuracy and efficiency.

Importance of Automation Control Components

Improved Efficiency – Automation reduces downtime and increases production speed.

Enhanced Accuracy – Precision control minimizes errors and defects.

Energy Savings – Optimized systems help in reducing power consumption.

Operational Safety – Automation minimizes risks in hazardous environments.

Scalability – Automated systems can be easily expanded for growing business needs.

Hikari Automation Systems Pte Ltd: A Trusted Partner for Automation

About Hikari Automation Systems Pte Ltd

With years of experience in automation technology, Hikari Automation Systems Pte Ltd is a leading name in automation control components in Singapore. The company specializes in providing high-performance, durable, and technologically advanced automation solutions for industries such as manufacturing, logistics, healthcare, and electronics.

Commitment to Quality and Innovation

Hikari Automation Systems Pte Ltd focuses on:

Cutting-edge technology to keep pace with industry advancements.

High-quality control standards ensuring reliable and long-lasting components.

Customizable solutions to meet specific industrial requirements.

Strong after-sales support with maintenance and troubleshooting services.

Key Automation Control Components Offered by Hikari Automation Systems Pte Ltd

1. Programmable Logic Controllers (PLCs)

PLCs are the backbone of industrial automation. Hikari Automation Systems Pte Ltd provides high-performance PLCs that offer:

Seamless integration with industrial equipment

Flexible programming for various applications

Fast and reliable data processing

2. Human-Machine Interfaces (HMIs)

HMIs enable operators to interact with machines efficiently. Hikari Automation Systems Pte Ltd offers user-friendly and high-resolution HMIs with:

Intuitive touchscreen displays

Remote monitoring capabilities

Real-time data visualization

3. Sensors and Encoders

Sensors and encoders are crucial for monitoring motion, pressure, temperature, and other parameters in automated systems. The company provides:

Proximity sensors for non-contact detection

Photoelectric sensors for object detection

Rotary encoders for precise motion control

4. Motor Drives and Motion Controllers

Hikari Automation Systems Pte Ltd offers advanced motor drives and motion controllers for smooth and accurate movement in automated machines. These components help in:

Regulating motor speed and torque

Enhancing precision in robotic systems

Reducing energy consumption

5. Industrial Relays and Contactors

Industrial relays and contactors play a vital role in controlling power circuits and ensuring system protection. Hikari Automation Systems Pte Ltd provides:

Electromagnetic and solid-state relays

High-capacity contactors for industrial applications

Reliable switching solutions

6. Power Supplies and Circuit Protection Devices

Ensuring stable power supply and circuit protection is essential for automation systems. The company’s offerings include:

Uninterruptible power supplies (UPS) for continuous operation

Surge protectors and circuit breakers for safety

Efficient power distribution units (PDUs)

Industries That Benefit from Hikari Automation Systems’ Components

Manufacturing

Enhances production efficiency

Reduces manual errors

Improves product consistency

Logistics and Warehousing

Enables automated sorting and packaging

Improves supply chain efficiency

Ensures faster and error-free operations

Healthcare and Pharmaceuticals

Supports precision medical equipment

Enhances laboratory automation

Ensures stringent quality control

Electronics and Semiconductor

Enables high-precision manufacturing

Enhances production speed

Reduces electronic component defects

Why Choose Hikari Automation Systems Pte Ltd?

Comprehensive Product Range

Hikari Automation Systems Pte Ltd offers an extensive selection of automation control components, ensuring complete solutions for diverse industries.

High-Quality and Reliable Solutions

All products are manufactured to meet international safety and quality standards, ensuring long-term reliability and performance.

Customized Automation Solutions

Tailored automation solutions are available to meet specific industrial needs, enhancing productivity and efficiency.

Technical Support and After-Sales Service

The company provides excellent technical support, maintenance, and troubleshooting services to keep systems running smoothly.

Frequently Asked Questions (FAQ)

1. What types of automation control components does Hikari Automation Systems Pte Ltd provide?

Hikari Automation Systems Pte Ltd offers PLCs, HMIs, sensors, encoders, motor drives, relays, contactors, power supplies, and circuit protection devices for industrial automation.

2. Are the products compatible with existing automation systems?

Yes, the company provides components compatible with various automation platforms, ensuring seamless integration with existing systems.

3. Does Hikari Automation Systems Pte Ltd offer customized automation solutions?

Yes, customized solutions are available to meet specific industrial automation requirements based on business needs.

4. How does automation improve operational efficiency?

Automation reduces manual errors, enhances precision, speeds up production, and lowers operational costs, resulting in increased efficiency and productivity.

5. Can these automation components be used for small and large-scale applications?

Yes, Hikari Automation Systems Pte Ltd caters to both small-scale and large-scale industrial automation requirements.

6. Does the company provide installation and maintenance services?

Yes, the company offers installation assistance, technical support, and maintenance services to ensure smooth operation of automation systems.

7. Are the automation control components energy-efficient?

Yes, the components are designed to optimize energy consumption, contributing to lower operational costs and sustainable practices.

8. Where can businesses purchase Hikari Automation Systems Pte Ltd products?

Businesses can contact Hikari Automation Systems Pte Ltd directly through their official website, authorized distributors, or customer service for product inquiries and purchases.

Conclusion

Automation control components are essential for industrial success, enabling efficient, precise, and cost-effective operations. Hikari Automation Systems Pte Ltd remains a trusted provider of high-quality automation control components in Singapore, offering innovative solutions tailored to various industries. With a strong commitment to quality, reliability, and customer support, Hikari Automation Systems Pte Ltd continues to lead the way in industrial automation technology.

For businesses seeking advanced automation solutions, Hikari Automation Systems Pte Ltd is the ideal partner for reliable, efficient, and future-ready automation control components.

1 note

·

View note

Text

Moza Racing Sim: The Ultimate Sim Racing Experience with Moza Racing Wheel and Moza Sim Racing Gear

Sim racing has become an essential part of the motorsport world, offering a realistic and immersive driving experience for both casual gamers and professional racers. Among the top brands in the industry, Moza Racing Sim stands out as a premium provider of high-quality sim racing equipment. From their Moza Racing Wheel to their direct drive wheelbases, pedals, and accessories, Moza has developed a reputation for delivering cutting-edge technology, precision control, and unmatched realism.

In this blog, we’ll take a deep dive into Moza Sim Racing, explore its top products, and discuss how it can elevate your racing experience to the next level.

Why Choose Moza Sim Racing?

1. Advanced Direct Drive Technology

One of the standout features of Moza Sim Racing is its direct drive wheelbases, which provide instant and detailed force feedback. Unlike traditional belt-driven wheels, Moza Racing Wheels use direct drive motors that deliver a stronger, smoother, and more precise driving feel.

✅ Stronger torque output for realistic force feedback ✅ No latency, ensuring a real-time driving response ✅ More durability and longevity compared to belt-driven systems

For racers looking for high-end performance without breaking the bank, Moza’s direct drive wheels are an excellent option.

2. High-Quality Build and Materials

Moza’s products are built with aircraft-grade aluminum, carbon fiber, and durable leather, ensuring a premium feel and long-lasting performance. Their racing wheels are designed for both comfort and control, making them ideal for long endurance races and competitive esports racing.

3. Versatile and Customizable Ecosystem

Moza Racing offers a wide range of products that work seamlessly together, including:

✔ Moza Racing Wheels – Formula, GT, and rally-style wheels ✔ Moza Direct Drive Wheelbases – From entry-level to professional-grade setups ✔ Moza Pedals – Adjustable and high-precision pedals for realistic braking ✔ Moza Sim Racing Accessories – Quick-release adapters, button boxes, and handbrakes

By combining these products, racers can create a customized setup tailored to their driving style.

Exploring the Best Moza Racing Wheels

Moza offers several high-performance racing wheels, each designed for different racing disciplines.

1. Moza KS Racing Wheel – Formula-Style Racing

The Moza KS Racing Wheel is perfect for Formula racing, GT3, and endurance races.

🔹 Lightweight carbon fiber construction for precise handling 🔹 Programmable buttons and rotary encoders for easy in-race adjustments 🔹 Magnetic paddle shifters for fast and responsive gear changes

If you’re into F1 racing or high-speed GT events, the Moza KS Racing Wheel delivers the perfect combination of control and comfort.

2. Moza ES Steering Wheel – Entry-Level Excellence

For beginners or those upgrading from a Logitech or Thrustmaster wheel, the Moza ES Steering Wheel offers:

🔸 Ergonomic rubber grips for comfort 🔸 Customizable button layout for personalized controls 🔸 Strong and responsive force feedback when paired with a Moza direct drive wheelbase

This wheel is great for all-around sim racing, making it a perfect entry-level choice.

3. Moza RS V2 Racing Wheel – Best for GT Racing

If you love GT racing, endurance racing, or street racing simulations, the Moza RS V2 Racing Wheel is a fantastic option.

✔ Premium leather grip for a luxurious feel ✔ Multiple inputs for mapping race functions ✔ Quick-release system for easy swaps between different wheel types

The Moza RS V2 offers an authentic racing experience for both casual and competitive drivers.

Moza Sim Racing Wheelbases: Direct Drive Power for Every Racer

1. Moza R5 Wheel Base – Perfect for Beginners

The Moza R5 Wheel Base is an entry-level direct drive system that provides 5Nm of torque, making it a great starting point for sim racers.

✅ Compact and lightweight design for easy setup ✅ Direct drive motor for superior force feedback ✅ Compatible with Moza racing wheels and pedals

If you’re upgrading from a belt-driven system, the Moza R5 is an affordable way to experience direct drive technology.

2. Moza R9 Wheel Base – Best for Intermediate Racers

For those looking for a mid-range wheelbase with more power, the Moza R9 offers 9Nm of torque for even stronger and more detailed force feedback.

✔ High-speed direct drive motor for instant response ✔ Zero-latency wireless technology for seamless communication with Moza accessories ✔ Custom tuning options via Moza Pit House software

This wheelbase is perfect for serious sim racers who want a balance of power and affordability.

3. Moza R16 and R21 Wheel Bases – Pro-Level Performance

For those who want the best of the best, the Moza R16 (16Nm) and R21 (21Nm) wheelbases provide:

🔥 Ultra-strong torque output for maximum realism 🔥 Ultra-responsive force feedback with high-detail precision 🔥 Ideal for professional esports racing and high-end sim setups

With these powerful wheelbases, Moza Racing Sim competes with Fanatec and Simucube in the high-end racing market.

Moza Sim Racing Accessories: Completing the Ultimate Setup

To fully optimize your racing rig, Moza offers a range of accessories that enhance performance.

Moza CRP Pedals – Precision Braking and Throttle Control

The Moza CRP Pedals feature:

✅ Load cell braking for realistic pedal feel ✅ Adjustable pressure settings for personalized control ✅ Durable metal construction for long-lasting performance

These pedals provide accurate braking force, making them essential for competitive racing.

Moza HBP Handbrake – Essential for Rally and Drifting

For those who enjoy rally racing or drifting, the Moza HBP Handbrake offers:

✔ Hall effect sensor for smooth braking force ✔ Adjustable travel distance and resistance ✔ Durability for aggressive use

This adds another level of control for off-road and drifting events.

Why Moza Racing Sim is the Best Choice for Sim Racers

Moza Sim Racing provides high-quality, customizable, and immersive racing gear for all levels of drivers.

✅ Affordable entry-level options (Moza R5 & ES Steering Wheel) ✅ High-performance mid-range gear (Moza R9 & RS V2 Racing Wheel) ✅ Pro-level direct drive systems (Moza R16 & R21) ✅ Top-tier pedals, handbrakes, and quick-release adaptersIf you’re looking for the best Moza racing wheel, wheelbase, and accessories, investing in Moza Sim Racing gear will take your driving experience to the next level.

0 notes

Text

Hollow Shaft Rotary Encoders in Automation: Key Benefits

Discover how hollow shaft rotary encoders simplify installation, save space, and boost automation efficiency across industries like textile, packaging, and hoisting.

0 notes

Text

Pepperl Fuchs | Incremental Rotary Encoder 14143613600Y47043

The Pepperl+Fuchs Incremental Rotary Encoder 14143613600Y47043 is a high-performance, reliable device designed to provide precise and accurate rotational measurements in industrial automation systems. As part of Pepperl+Fuchs' renowned series of sensors, this incremental rotary encoder plays a critical role in monitoring and controlling rotational movements in machinery, robotics, and other applications where position feedback is essential.

This particular model is designed with a robust construction, ensuring durability and long-lasting performance even in demanding environments. It uses incremental encoding technology to detect the angular position of a rotating shaft and convert it into an electrical signal that can be easily interpreted by control systems and machinery. The encoder produces a series of pulses, which represent the rotational movement, allowing precise speed and position control.

Key Features:

Incremental Output: The encoder provides incremental signals, typically in quadrature format, which are used to measure both rotational speed and position. This makes it ideal for applications requiring continuous feedback and motion control.

High Precision and Accuracy: Designed to meet high standards of precision, the encoder ensures accurate measurements of rotational movements. It is suitable for applications that demand high resolution and repeatability, such as industrial automation, robotics, and CNC machinery.

Durable and Robust Design: The Pepperl+Fuchs Incremental Rotary Encoder is built to withstand harsh conditions, including vibration, dust, moisture, and temperature fluctuations. Its sturdy housing ensures reliable performance in tough environments.

Versatile Mounting Options: With flexible mounting and connection options, this encoder can be easily integrated into a variety of machines and equipment, making it a versatile choice for OEMs and system integrators.

Wide Range of Applications: This model is ideal for use in applications where rotational position feedback is essential, including in conveyor systems, motors, actuators, pumps, and more. It can also be used in packaging, automotive, and material handling industries.

Easy Installation and Integration: The encoder is designed for quick and easy integration into existing systems, with minimal setup required. Its compatibility with a wide range of control systems makes it a convenient option for a variety of industrial sectors.

Specifications:

Model Number: 14143613600Y47043

Type: Incremental Rotary Encoder

Resolution: Offers high-resolution pulse output for detailed position feedback.

Electrical Interface: Typically available in standard formats like TTL or HTL, ensuring compatibility with various control systems.

Shaft Diameter: Available in different shaft sizes to meet specific mechanical requirements.

Power Supply: The encoder operates on a wide range of supply voltages, ensuring flexibility for various setups.

The Pepperl+Fuchs 14143613600Y47043 Incremental Rotary Encoder is a reliable and cost-effective solution for applications that require precise motion control. Whether in a factory automation system, a robotics project, or an industrial machine, this encoder delivers dependable performance, ensuring smooth operation and optimal productivity. Its high accuracy, robust construction, and easy integration make it a top choice for professionals in industrial and automation fields.

1 note

·

View note

Text

The Science Behind Hollow Shaft Rotary Encoders: Torque, Speed, and Accuracy

In the landscape of modern automation, sensors and feedback mechanisms are crucial for maintaining the precision and efficiency of machinery. One of the most indispensable devices in this category is the rotary encoder, especially the hollow shaft rotary encoder. These devices provide real-time data on angular position, velocity, and direction, enabling refined control over dynamic systems. Their unique hollow shaft design offers numerous advantages, particularly when integrating with rotating shafts and assemblies in compact or sensitive environments. This article delves into the scientific underpinnings of these encoders, examining how they measure torque, speed, and accuracy in industrial and robotic applications.

Basics of Rotary Encoders

Rotary encoders translate rotational motion into digital signals. They are broadly categorized into absolute and incremental types. Absolute encoders deliver a unique position value, whereas incremental encoders provide relative motion data. Hollow shaft rotary encoders, a sub-type of these devices, allow the shaft of the motor or machinery to pass through the encoder. This design minimizes axial load, reduces mechanical complexity, and facilitates easier installation. The hollow shaft construction is particularly beneficial in applications where space is limited or where quick replacement and alignment are essential. These encoders are primarily used in robotics, CNC machinery, elevators, and energy sector equipment.

Working Principle of Hollow Shaft Rotary Encoders

Hollow shaft rotary encoders typically use optical, magnetic, or capacitive sensing methods. Optical encoders employ a light source and photodetector array to read patterns on a rotating disk. Magnetic encoders detect changes in magnetic fields using Hall-effect sensors or magnetoresistive elements. Capacitive encoders utilize variations in capacitance caused by changes in geometry as the shaft rotates. Each method has its advantages in terms of resolution, durability, and environmental robustness. The hollow shaft design does not alter the fundamental sensing mechanism but allows the encoder to be mounted directly over a rotating shaft without additional couplings. This direct interface helps reduce backlash and enhances accuracy.

Measuring Torque with Hollow Shaft Rotary Encoders

Torque is the rotational analog of linear force. Although rotary encoders are not traditionally used as torque sensors, they play a significant role in torque estimation. By precisely measuring angular displacement and speed, and knowing the system's moment of inertia, torque can be inferred. In applications where torque sensors are either too bulky or expensive, high-resolution encoders serve as a cost-effective alternative. The key lies in correlating the angular velocity and acceleration data provided by the encoder with the mechanical characteristics of the system. For dynamic torque measurement, especially in systems with varying load conditions, encoders offer real-time feedback that can be analyzed via control algorithms to maintain performance consistency.

Speed Detection in Dynamic Systems

Speed detection is a primary function of rotary encoders. Incremental hollow shaft rotary encoders are particularly adept at delivering high-fidelity speed data. They generate pulses for every increment of rotation, which are counted over time to calculate speed. Higher pulse counts per revolution (PPR) mean greater resolution and more accurate speed readings. In applications like conveyor systems, turbines, or robotic joints, this level of speed precision ensures smoother operation and reduces wear and tear. Encoders are also favored for their minimal latency, allowing near-instantaneous speed adjustments. Furthermore, their digital output can be seamlessly integrated into programmable logic controllers (PLCs) or microcontrollers for real-time processing and control.

Ensuring Accuracy and Resolution

Accuracy in rotary encoders refers to the degree to which the measured position matches the actual position. Resolution, on the other hand, is the smallest change in position that the encoder can detect. High-resolution encoders are essential for systems requiring fine control, such as semiconductor manufacturing or surgical robotics. Hollow shaft rotary encoders often offer both high resolution and excellent accuracy due to their ability to directly interface with the rotating element. This reduces mechanical errors associated with couplings or misalignment. Optical encoders typically offer the highest resolution, while magnetic and capacitive types provide better resilience in harsh environments. Calibration and alignment during installation also play critical roles in maintaining accuracy.

The Importance of Zero Backlash

Backlash is the slight movement that occurs when direction is reversed in a mechanical system. This can cause significant errors in position sensing. Hollow shaft encoders help minimize backlash by allowing direct mounting onto the shaft, thereby eliminating intermediate couplings or gears that can introduce slack. Zero backlash is particularly critical in high-precision applications like robotics and CNC machining, where even minor errors can lead to defective outcomes. By integrating the encoder directly onto the shaft, manufacturers can achieve tighter control loops, reduced error margins, and more reliable performance. This direct integration also facilitates better synchronization between motor movement and feedback, enhancing overall system stability.

Environmental and Structural Considerations

Industrial environments often expose equipment to dust, moisture, temperature fluctuations, and vibrations. Hollow shaft rotary encoders are designed to withstand these conditions through robust housing, sealed bearings, and non-contact sensing technologies. Magnetic and capacitive encoders are particularly well-suited for such environments due to their resistance to contaminants and mechanical wear. Structural considerations also include the material of the encoder’s housing and shaft, which must align with the application’s requirements for durability and weight. The hollow shaft itself can be designed to accommodate different shaft diameters, increasing its adaptability across multiple systems. Proper installation and maintenance further ensure the encoder's longevity and consistent performance.

Integration into Closed-Loop Systems

Hollow shaft rotary encoders play a pivotal role in closed-loop control systems, where feedback is used to adjust and correct motion in real time. These systems require high-resolution and low-latency feedback to maintain accuracy and efficiency. The encoder sends position and speed data to a controller, which then adjusts the motor’s operation accordingly. This continuous feedback loop allows for precise control even in variable load conditions. Integration into such systems requires compatibility with control hardware, appropriate signal output formats, and real-time data processing capabilities. Encoders that support multiple output protocols, such as quadrature, SSI, or BiSS, offer greater flexibility in system design.

Case Study: Hollow Shaft Encoders in Robotic Arms

Robotic arms require exceptional precision and agility, often functioning in environments that demand both speed and safety. Hollow shaft rotary encoders enable these capabilities by offering accurate position and velocity feedback without adding bulk to the joints. Their compact design fits seamlessly into tight spaces, while their direct shaft interface ensures minimal mechanical error. For example, in medical robotics, where minute movements can have significant consequences, the encoder's resolution and accuracy become critical. Additionally, their ability to function reliably in varying environmental conditions makes them suitable for both cleanrooms and industrial settings. This case study illustrates how the theoretical benefits of hollow shaft encoders translate into practical performance gains.

Comparing Hollow Shaft and Solid Shaft Encoders

Solid shaft encoders require couplings or adapters for installation, which can introduce alignment issues and mechanical play. Hollow shaft encoders bypass these challenges by mounting directly onto the shaft, thereby reducing complexity and improving measurement fidelity. While solid shaft designs may offer slightly more mechanical robustness, they often necessitate more space and careful alignment. Hollow shaft encoders, by contrast, are easier to install and replace, which is beneficial in systems where downtime must be minimized. The choice between the two often comes down to the specific application requirements, including available space, desired precision, and environmental factors. Ultimately, hollow shaft models offer a compelling mix of convenience and performance.

Market Trends and Future Outlook

The market for rotary encoders is evolving rapidly, driven by advancements in automation, robotics, and smart manufacturing. Hollow shaft rotary encoders are gaining traction due to their compact design and enhanced integration capabilities. Innovations such as wireless data transmission, miniaturization, and improved environmental resistance are expanding their application scope. Additionally, the incorporation of edge computing and AI into encoder systems is enabling predictive maintenance and smarter feedback mechanisms. As industries continue to push for higher efficiency and precision, the demand for reliable and versatile encoders will only increase. In this context, the hollow shaft encoder emerges as a key component in future-ready systems.

Conclusion

The science behind hollow shaft rotary encoders encompasses a multidisciplinary understanding of mechanics, electronics, and systems engineering. Their ability to provide accurate, real-time data on torque, speed, and position makes them invaluable in a wide array of industrial and robotic applications. Their unique hollow design simplifies installation and enhances performance by reducing mechanical errors. From aiding in torque estimation to ensuring zero backlash and high-resolution feedback, these encoders are tailored for precision-driven environments. As technological advancements continue to refine their capabilities, the hollow shaft rotary encoder is poised to remain a cornerstone of intelligent motion control systems across industries.

0 notes

Text

0 notes

Text

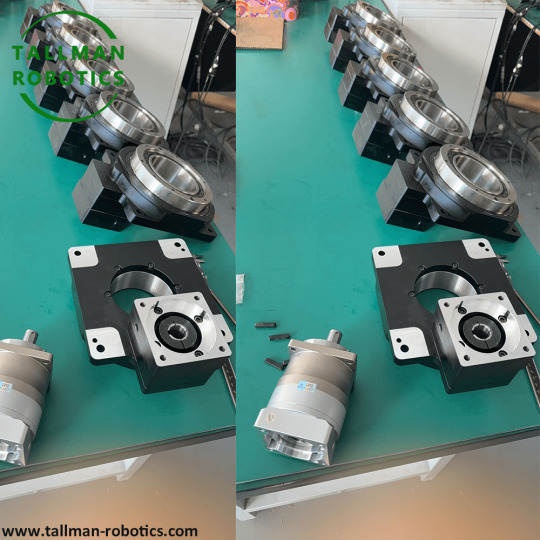

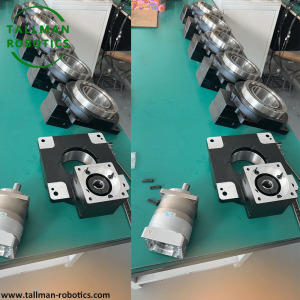

Precise Positioning Hollow Rotary Tables Will Be Delivered to Pakistan

Precise Positioning Hollow Rotary Tables are specialized rotational devices featuring a central hollow shaft, designed for high-accuracy angular positioning. The hollow core allows cables, pneumatic lines, or shafts to pass through, eliminating cable tangling and reducing system complexity.

https://youtu.be/ZP31od3m6Xc?si=KSzfpuXjjSW-2xnV Key Components and Features 1. Drive Mechanisms: Harmonic Drives: Preferred for near-zero backlash and high torque density. Direct Drive Motors: Offer smooth operation and precise control without mechanical reduction. Alternative systems like worm gears may be used but are less common in ultra-high-precision settings. 2. Bearings: Crossed Roller Bearings: Provide high rigidity and accuracy, handling both radial and axial loads efficiently. 3. Feedback Systems: High-resolution absolute encoders ensure accurate position tracking, even after power interruptions. 4. Materials and Construction: Made from rigid materials like aluminum or steel alloys to minimize deflection under load. Standardized mounting interfaces (e.g., ISO/SAE flanges) for easy integration with machinery. Applications of Large hollow shaft rotary tables CNC Machining: Enables multi-axis machining by rotating workpieces precisely. Semiconductor Manufacturing: Used in wafer handling and inspection systems. Optics and Medical Devices: Positions lenses or surgical tools with high accuracy. Robotics: Facilitates precise joint movements in automation and articulated robots. Advantages Over Standard Rotary Tables Hollow Design: Central pass-through avoids cable management issues, enhancing reliability. High Precision: Sub-arc-minute accuracy achievable with advanced feedback and drive systems. Versatility: Suitable for diverse industries due to customizable sizes and load capacities. Conclusion Precise Positioning Hollow Rotary Tables/Large hollow shaft rotary tables are critical in applications demanding exact angular positioning with central component pass-through. Their design combines mechanical precision with intelligent feedback systems, making them indispensable in advanced manufacturing and automation. You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#CNCHollowRotaryActuator#HeavyDutyHollowRotaryTables#HighPrecisionHollowRotaryTablesforCNCMachines#High-precisionrotarytable#HollowAxes#HollowRotaryPlatform#HollowRotaryTableRightAngleManufacturer#LargeApertureHollowRotaryTables#Largehollowshaftrotarytables#PlanetaryGearboxes#PrecisePositioningHollowRotaryTables#PrecisionHollowRotaryTable#PrecisionRightAngleRotaryTables#RotaryActuators

0 notes

Text

0 notes

Text

Jayashree Encoders provides Rotary Encoder, hollow shaft rotary encoder, incremental encoder, htl encoder at best price. It is the best rotary encoder Supplier, Manufacturer, Exporter, Dealer company in Pune, Mumbai, Kolkata, Bangalore, Gujrat, Amravati, Nashik, Chennai, Tamilnadu, Nagpur, Ahmednagar, Satara, Sangli, Delhi, UP, MP, Madhya Pradesh, India. With over 25 years of expertise, we are proud to be leaders in the manufacturing of optical encoders. As a trusted industry expert, we have a proven track record of delivering high-quality, reliable, and precise optical encoders for various industries and applications. Explore our website to learn more about our optical encoders, capabilities, and services. Contact us today to discuss your optical encoder needs and experience the expertise and quality that sets us apart.

0 notes